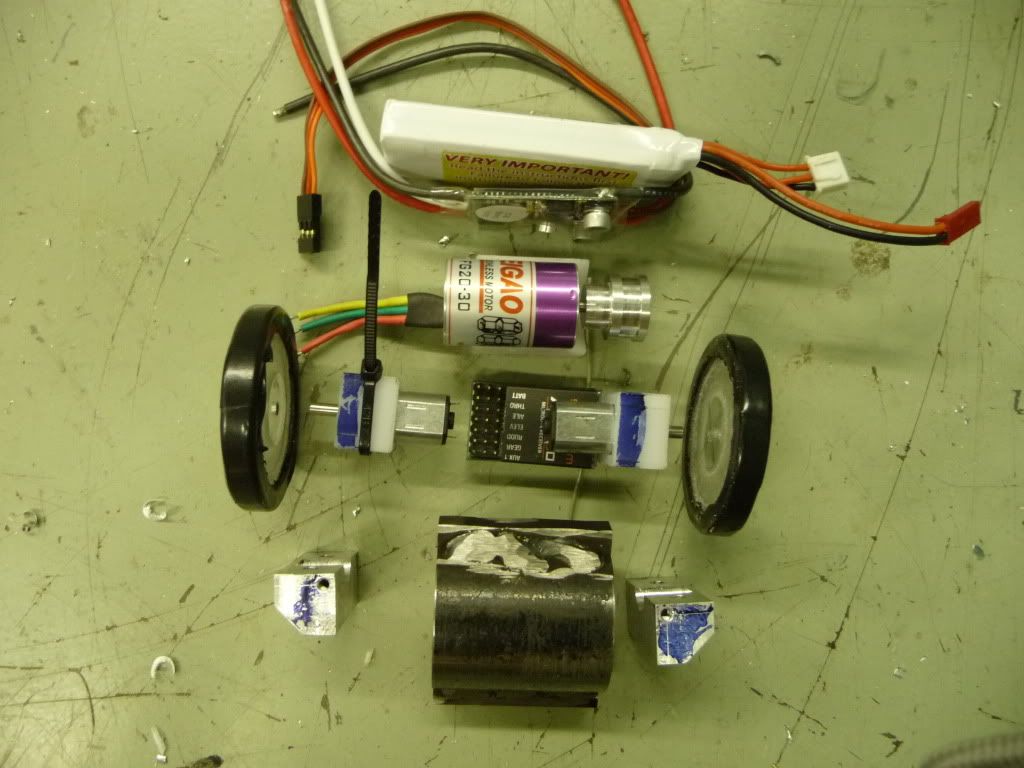

- the pulley and bearing cups on either side of the drum

- the top armor

- the frame

I still have to put set screws in the wheels (and open the holes enough for the motor shafts to fit through) but everything is coming together.

The drum is done. I actually ended up with two because after I made the first one, my dad told me a better way to do it (which really should have been quite obvious) and I did it all again - better. I made a small welding mistake that means I'm only going to be able to get three screws in instead of four, but I guess it could have been worse...

The drum is done. I actually ended up with two because after I made the first one, my dad told me a better way to do it (which really should have been quite obvious) and I did it all again - better. I made a small welding mistake that means I'm only going to be able to get three screws in instead of four, but I guess it could have been worse... The front corner blocks are both done (I made the first a few days ago, but messed up the second so I finally remade it today). They're so SMALL! I'm used to copperhead's which weigh 1.5 lbs. These don't even weigh 1.5 ounces together! I ordered my shaft, bearings, top armor, and hardware today. Hopefully that will all come in the next few days.

The front corner blocks are both done (I made the first a few days ago, but messed up the second so I finally remade it today). They're so SMALL! I'm used to copperhead's which weigh 1.5 lbs. These don't even weigh 1.5 ounces together! I ordered my shaft, bearings, top armor, and hardware today. Hopefully that will all come in the next few days.

I made my wheels too! They're made out of a Lexan equivalent, with electrical tape tires. It's kind of an experiment so we'll see how well it works.

I bought the big block of aluminum for my frame today too. It's 2099 alloy, which is actually extremely hard to find. I have no idea how much it would have been as prime stock, because I bought it as a usable drop (sold by weight of aluminum regardless of alloy). 2099 was developed in 2006 by a company called Alcoa Innovation for use in the aerospace industry. It is very impact resistant and rigid, and lighter than 6061 and 7075. According to the Alcoa website, it is 7-17% lighter that traditional aerospace aluminum, and

has an expected lifetime of 1.5 to 3 times that of traditional alloys. It's actually an alloy of aluminum with lithium, and won Alcoa the prestigious R&D 100 award for its development.

has an expected lifetime of 1.5 to 3 times that of traditional alloys. It's actually an alloy of aluminum with lithium, and won Alcoa the prestigious R&D 100 award for its development.I'm debating moving the wheels back and putting the weapon motor in front of them. This will mean a shorter belt that doesn't need rollers and other stuff, but less weight over the drive wheels. But maybe it will drive better with the wheels further back... We'll see. It will probably force me to lengthen the frame by a 1/4 inch, which adds weight that I can't afford to add. Hopefully I can get away with a belt that goes through my drive motor mount and keeps to my original design... it's just such a better layout...

And believe it or not, there IS another antweight quietly being built alongside this one. I can't release any details, that's up to it's owner Jeff, but it should be competing with mine at BARF and GCRS2.

No comments:

Post a Comment